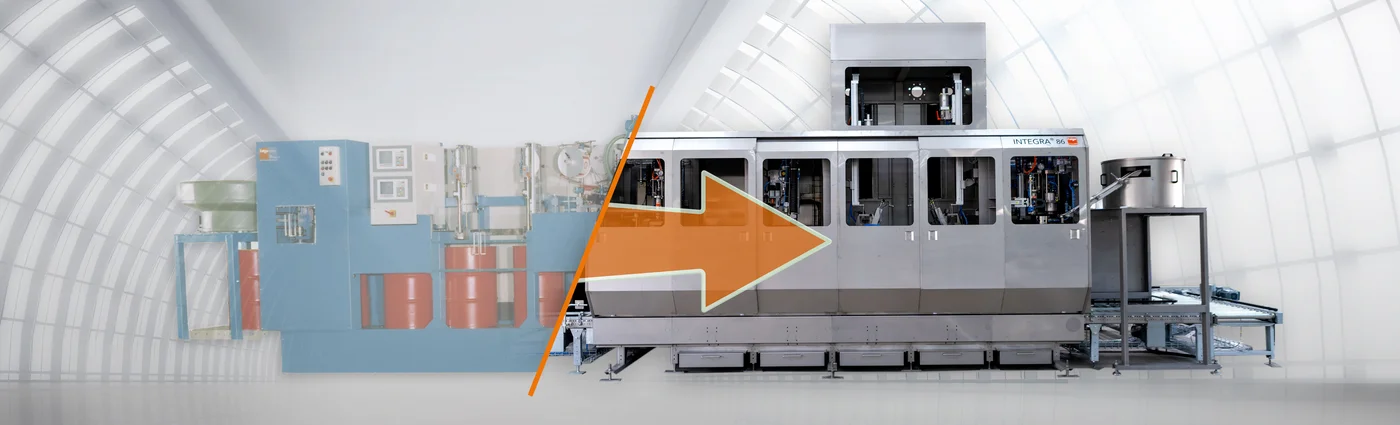

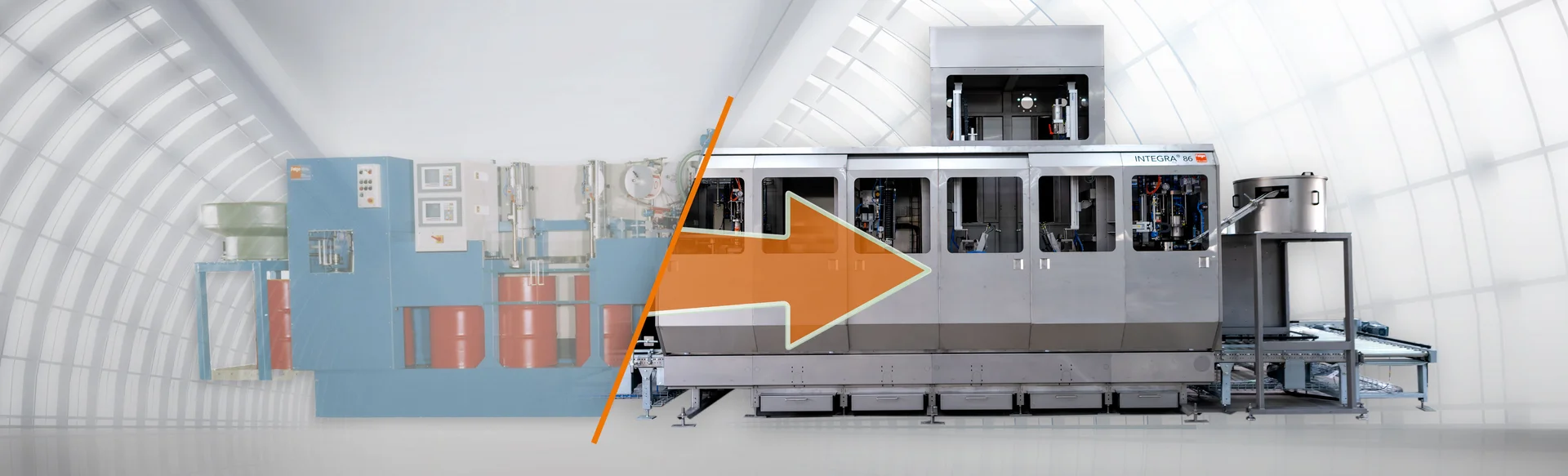

Your equipment is no longer up-to-date?

We are there for you – together we will work out an efficient solution!

No problem! Our experienced engineers and technicians will work hand in hand with you to develop a custom-tailored modernisation concept that implements your new requirements in an ideal manner.

For numerous scenarios, upgrading and updating an existing filling system, also known as retrofitting, is an exceedingly attractive alternative to purchasing a completely new system. Advanced control and weighing technologies can considerably increase the productivity and energy efficiency of the filling system.

This is what you will gain by optimising your equipment

Your benefits at a glance

-

Increased productivity and improved machine availability thanks to modern technologies

-

Retrofit option for phased out components

-

Low investment costs, simplified investment approval procedure and high ROI

-

Reduction of operating and maintenance costs

-

Fast commissioning and reduced downtimes due to adoption and retention of existing machine structure

-

Preservation of quality thanks to the use of original parts

-

12 months warranty

Not without FEIGE web HMI

The FEIGE web HMI was specifically developed keeping in mind the operators' requirements. It provides for greater productivity and transparency as well as shorter familiarisation times for new employees. Leading-edge visualisation options and recipe management with grouped parameters in addition offer an optimised overview. The web-based HMI with multi-touch and gesture control can be used even faster and easier due to the particularly intuitive design and smartphone-like operation – offering features such as drop-down boxes and slide switches. Another benefit: The interface runs on virtually any end device, such as mobile phones and tablets, it is platform-independent and can be operated on several devices at once. The logbook can be used to document different machine states.