Accurate pail filling for increased productivity

We fill your pails.

We offer you tailor-made filling technologies for your individual areas of application. Our decades of experience with innovative technology and our continuous adaptation to the changing requirements of the market guarantee the successful implementation of your desires.

Select the solution that matches your needs in the gravimetric filling of containers sized from 0.5 kg to 60 kg from our product range. The modular concept of Feige FILLING filling equipment satisfies any requirement.

Your requirements

- Different viscosities: Filling equipment that is designed for liquids with different viscosities, including high-viscosity and low-viscosity liquids.

- Abrasive products such as plasters require a special, high-resistance filling valve.

- Filling under pressure: Systems facilitating filling under pressure so that even viscous or difficult to handle products can be efficiently filled.

- Operator protection: Implementation of comprehensive security measures to protect operators against the dangers arising when handling hazardous substances.

- Consideration of environmental aspects: Systems and processes that are designed to mitigate the environmental impact by reducing the use of chemicals and working in an energy-efficient manner.

- Optimised working conditions: Layout of the working environment and the machines to minimise the health risks for employees and at the same time guarantee ease of operation.

- ATEX-compliant equipment: Special machines approved for the use in potentially explosive areas (ATEX zones) guarantee a smooth and reliable operation.

Always in the flow with FEIGE web HMI

The FEIGE web HMI was specifically developed with the operators’ needs in mind, increasing productivity and transparency and shortening the training time for new employees. To this end, state-of-the-art visualisation options and recipe administration with grouped parameters provide an optimised overview. Thanks to the particularly intuitive design and the smartphone-like operation such as drop-down boxes and slide switches – using the web-based HMI with multi-touch and gesture control has become even faster and easier. Another advantage: The interface runs on virtually any terminal, such as mobile phones and tablets, is platform-independent and can be operated on several devices simultaneously. Different system states can be documented in the logbook.

Overview of the benefits of the FEIGE web HMI:

- Productivity and transparency: Enhanced productivity due to increased transparency of processes.

- Short training times: New employees can be trained faster.

- Optimised overview: State-of-the-art visualisation options and recipe administration with grouped parameters provide a superior overview.

- Intuitive operation: Thanks to multi-touch, gesture control and a design reminiscent of a smartphone, utilisation becomes much easier.

- Independence of platforms: Runs on virtually any terminal, including mobile phones and tablets and can be operated on several devices simultaneously.

- Logbook function: Documentation of various system states for enhanced traceability and analysis.

- These features turn the FEIGE web HMI into a powerful solution that is specifically geared to meeting the operators’ needs and to increase production efficiency.

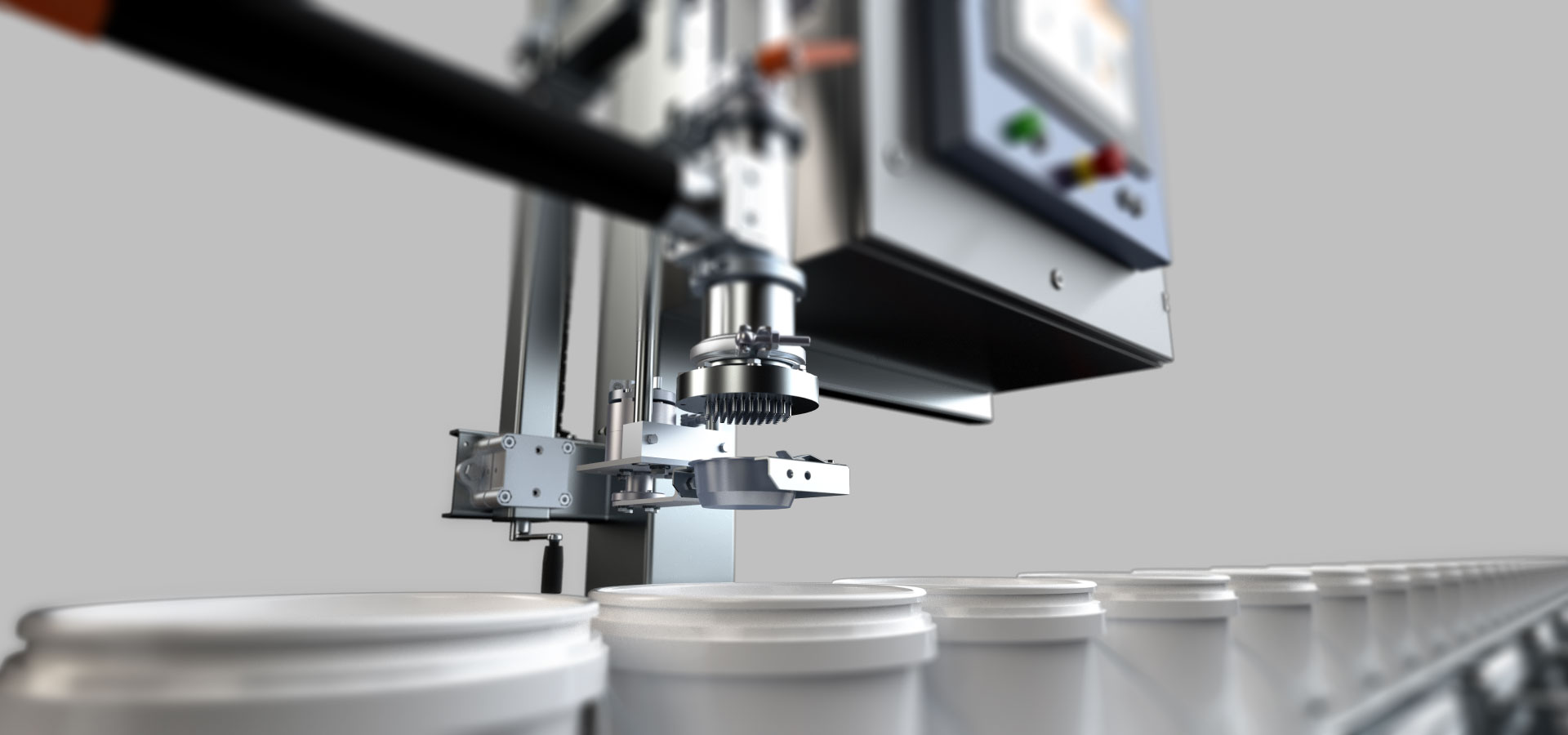

Our core competence: the filling valve

FEIGE filling machines impress with their premium components: the filling valve and the weigh scale.

The FEIGE filling valve enables you to fill your liquid and viscous products in a precise and flexible manner, either proportionally or in several stages. The filling operation is carried out in the well-proven coarse fill/fine fill mode, enabling an adjustment of the fine flow to your needs, depending on the product. Due to the precise restriction of the volumetric flow by a two-stage or analogue setting of the filling valve at the end of filling, calibration error limits are observed.

The filling valve is dimensioned according to your requirements with regard to filling opening, viscosity and volumetric flow. At the same time, FEIGE relies on high-grade materials such as stainless steel (1.4571/316Ti), Hastelloy, PVDF and coatings to ensure the reliability of the filling valve. In addition, heatable filling valves that are equipped with overflow protections are available for different areas of application.

Equipment features

- Quick-action stainless steel filling valve mount

- Hygienic, self-adjusting PTFE ring seal

- Bellows made from stainless steel or PTFE

- Valve tip and opening method according to product requirements

- Precise, clean and splash-free filling method

- Easy and efficient cleaning without dismounting

- Minimum of dead spaces

As a rule, FEIGE filling valves are compensated so that the product pressure inside the valve does not influence the opening or closing behaviour. Pressurised filling valves cannot open spontaneously, thus increasing safety. Cleaning the FEIGE filling valves is both easy and efficient as dismounting the valves is not necessary. Any components and seals are designed so that the filling valve is low of any dead spaces. The product hose is either connected directly without intermediate flange or in a flexible manner by means of any of the flange systems available on the market to suit your requirements or standards.

The properties of your product and the container type determine the filling mode. Which filling mode do you need?

Whether viscous products with high viscosities or highly fluid foodstuff, construction materials or chemicals – any of these substances necessitate a special filling method. We offer you comprehensive advice and together find the perfect solution for your specific needs!

![[Translate to English:] Niklas Gentes](/fileadmin/FeigeFilling/Mitarbeiterfotos/Niklas_Gentes.png)